1. Tensometer

This machine is used to perform tensile test to predict tensile strength of materials.

2.Rockwell Hardness Tester

Rockwell hardness tester is used to determine the surface hardness of the materials.Provisions to apply a major load of 60kgf,100kgf,and 150kgf are available in this machine.Itdirectly calculates the rockwell hardness value upon completion of the test.

3. Impact Tester

This is used to study the toughness or energy absorbing properties of various materials under two types of impact tests i.e Izod and charpy impact tests.

4.Simply Supported Beam setup

A simply supported beam is hinged at two ends and the load is applied at a point between the two hinges.

5.Fixed beam setup

It is a type of cantilever beam setup.

6. Compression Tester for Spring

This tester is used to obtain spring stiffness and their mechanical properties.

7. Surface Roughness Tester

Roughness tester shows the measured roughness depth as well as the mean roughness value in micrometers or microns.

8.Static UTM

This machine is used to perform tensile,compression,shear and bend test.It operates on hydraulic loading and can be controlled manually.The maximum load attainable is 200kN and maximum displacement is 200mm.

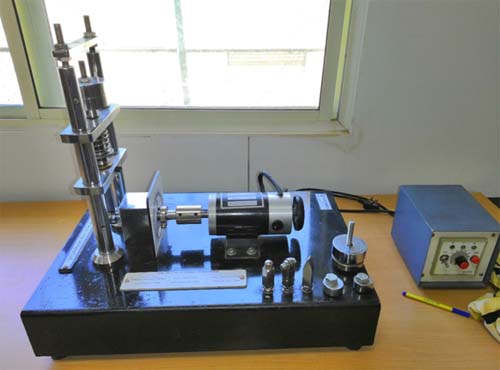

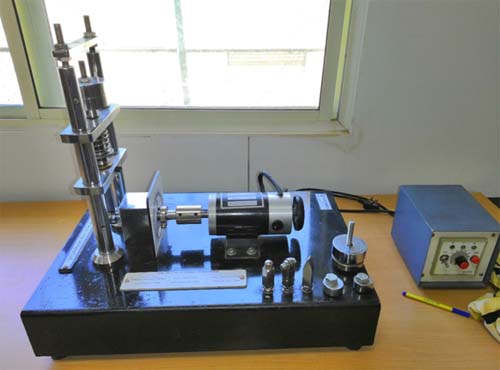

9. Torsion Tester

This tester is used to obtain twisting moment-twist relationship of a specimen and to determine shear modulus G,yield stress in pure shear,experimental ultimate torque.

10. Euler Buckling Apparatus

To determine the euler buckling load experimentally and compare it to the eulertheory.Also to study the effect of end conditions on the buckling load.

11. Dynamic UTM

Dynamic Universal Testing Systems are required to test the endurance and life of materials and product designs.

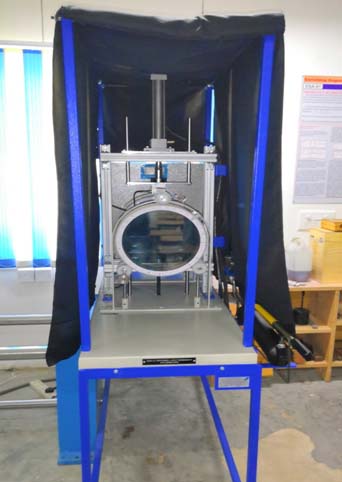

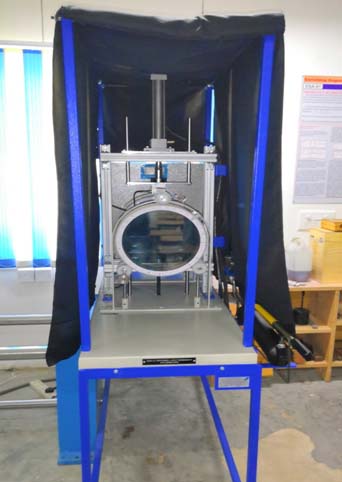

12. Diffused light Polariscope

This equipment is used to view and measure the principal stress components and directions of principal stresses by the photoelastic method for the plane stress condition at any given point in a photoelastic sample.

13. Stress Analysis on Thin Cylinder

To show the linearity of strain gauges in the open end condition in a thin cylinder,to fine the hoop stress and strain relationship for the cylinder material and to fine the longitudinal and hoop strain relationship.

14. Cam-Follower Apparatus

A cam follower, also known as a track follower,[1] is a specialized type of roller or needle bearing designed to follow cam lobe profiles. Cam followers come in a vast array of different configurations, however the most defining characteristic is how the cam follower mounts to its mating part; stud style cam followers use a stud while the yoke style has a hole through the middle.

15. Universal Governor

A governor, or speed limiter or controller, is a device used to measure and regulate the speed of a machine, such as an engine.

16. Gyroscope

Applications of gyroscopes include inertial navigation systems, such as in the Hubble Telescope, or inside the steel hull of a submerged submarine. Due to their precision, gyroscopes are also used in gyrotheodolites to maintain direction in tunnel mining.[4] Gyroscopes can be used to construct gyrocompasses, which complement or replace magnetic compasses (in ships, aircraft and spacecraft, vehicles in general), to assist in stability (bicycles, motorcycles, and ships) or be used as part of an inertial guidance system.

17. Kinematic Models

These are the small models of various mechanical equipments.

18. Journal Bearing Apparatus

A self-contained floor standing apparatus to fully investigate the effects of speed viscosity and load on the pressure distribution in a journal bearing.

19. Forces at reciprocating masses setup

A visible model of reciprocating I.C engine with cylinder and balancing masses loaded.

20. Epicyclic Gear Train

Epicyclic gearing or planetary gearing is a gear system consisting of one or more outer gears, or planet gears, revolving about a central, or sun gear. Typically, the planet gears are mounted on a movable arm or carrier, which itself may rotate relative to the sun gear. Epicyclic gearing systems also incorporate the use of an outer ring gear or annulus, which meshes with the planet gears.

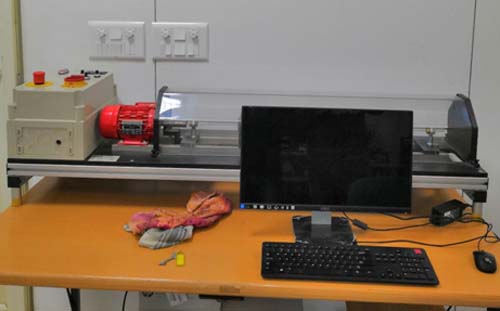

21. Fatigue Testing Machine

Fatigue test machines use static, dynamic, and fatigue tests to evaluate the sturdiness of raw materials, components or finished products.Fatigue tests help to determine a test sample's life expectancy under actual service loads in real-world applications.

22. Static & dynamic Balancing

This is suitable for conducting experiments on static balancing and dynamic balancing with different weights. This consists of rectangular frame of steel perfectly balance with four different blocks. A protractor scale of the disc is provided to reach exact angular position of each weight to be measured. A linear scale provided below the frame provides the measurement of each weight along the shaft. The unit is hanging from a rigid steel frame through chain for dynamic balancing and can be fixed rigidly for static balancing.specified .

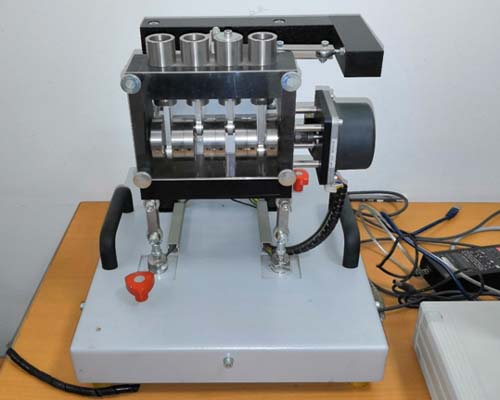

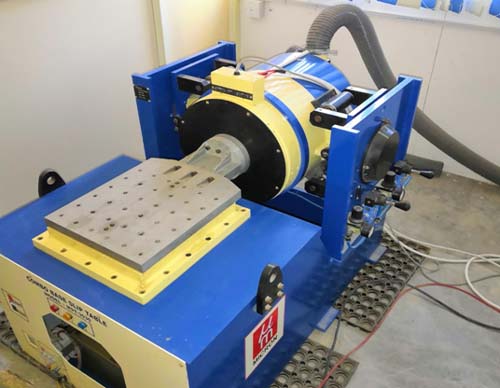

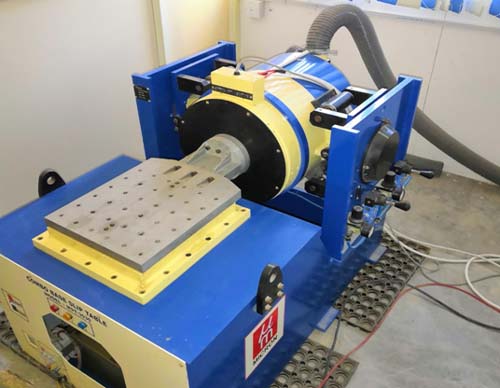

23. Pin & Disc Wear Apparatus

Pin on disk wear testing is a method of characterizing the coefficient of friction,frictional force and rate of wear between two materials.This testing can simulate multiple modes of wear,includingunideirectional,bidirectional,omni directional and quasi rotational.

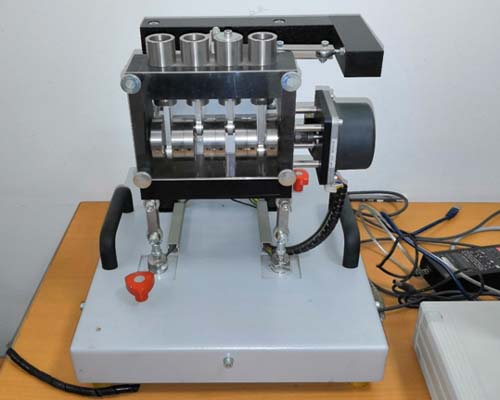

24. Slip & Creep Measurement Apparatus

Slip & Creep Measurement Apparatus. This apparatus is useful for measurement of power transmitted for various input power conditions with varied belt tension. Belt slip or creepalso can be measured. The apparatus consists of a variable speed motor, driving pulley and driven pulley of equal diameters.

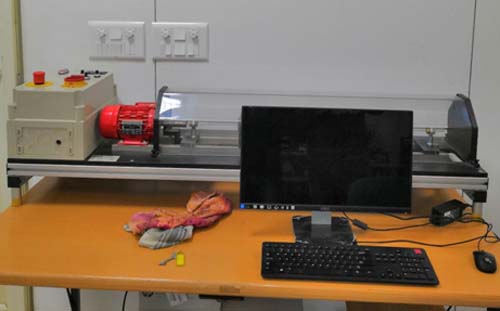

25.Whirling Shaft Apparatus

The Equipment shall have the following test facility:

1) To measure co-efficient of friction between pulley material and different belt materials.

2) To measure power transmitted with varied belt tension and plotting a graph of “Tension Characteristics”.

26.Universal vibration apparatus

This machine is used to

1) Equivalent spring mass system to study the undamped free vibration.

2) Equivalent spring mass system to study forced calibration.

27.Vibration Fundamental Trainer

The VFT is designed to perform both free and forced vibration experiments with and without damping. The pendulum vibration module includes a rod on which one or more mass can be attached. This basic module is designed to teach the fundamental principles such as frequency and period, and the concept of equivalent mass.

28. Vibration Shaker

Shakers are used to determine product or component performance under vibration or shock loads, detect flaws through modal analysis, verify product designs.

29.Piezo Actuation Unit

A piezo actuator can beused to control hydraulic valves, act as a small-volume pump or special-purpose motor, and in other applications requiring movement or force