Waste Water Management, IIT Mandi, Kamand Campus.

Waste water treatment is a process to convert wastewater into an effluent that can be either returned to the water cycle with minimal environmental issues or reused. The later is called water reclamation and implies avoidance of disposal by use of treated wastewater effluent for various purposes. Treatment means removing impurities from water being treated and some methods of treatment are applicable to both water and wastewater.Waste water treatment plants may be distinguished by the type of wastewater to be treated, ie.whether it is sewage,industrial wastewater and agricultural wastewater. Wastewater quality indicators include the following tests: Biochemical Oxygen Demand, Chemical Oxygen Demand, Coliform Index, Dissolved Oxygen, Heavy Metals, pH, Salinity,Temperature, Total Dissolved Solids, Total suspended solids, Oil & Grease ,Turbidity, etc.

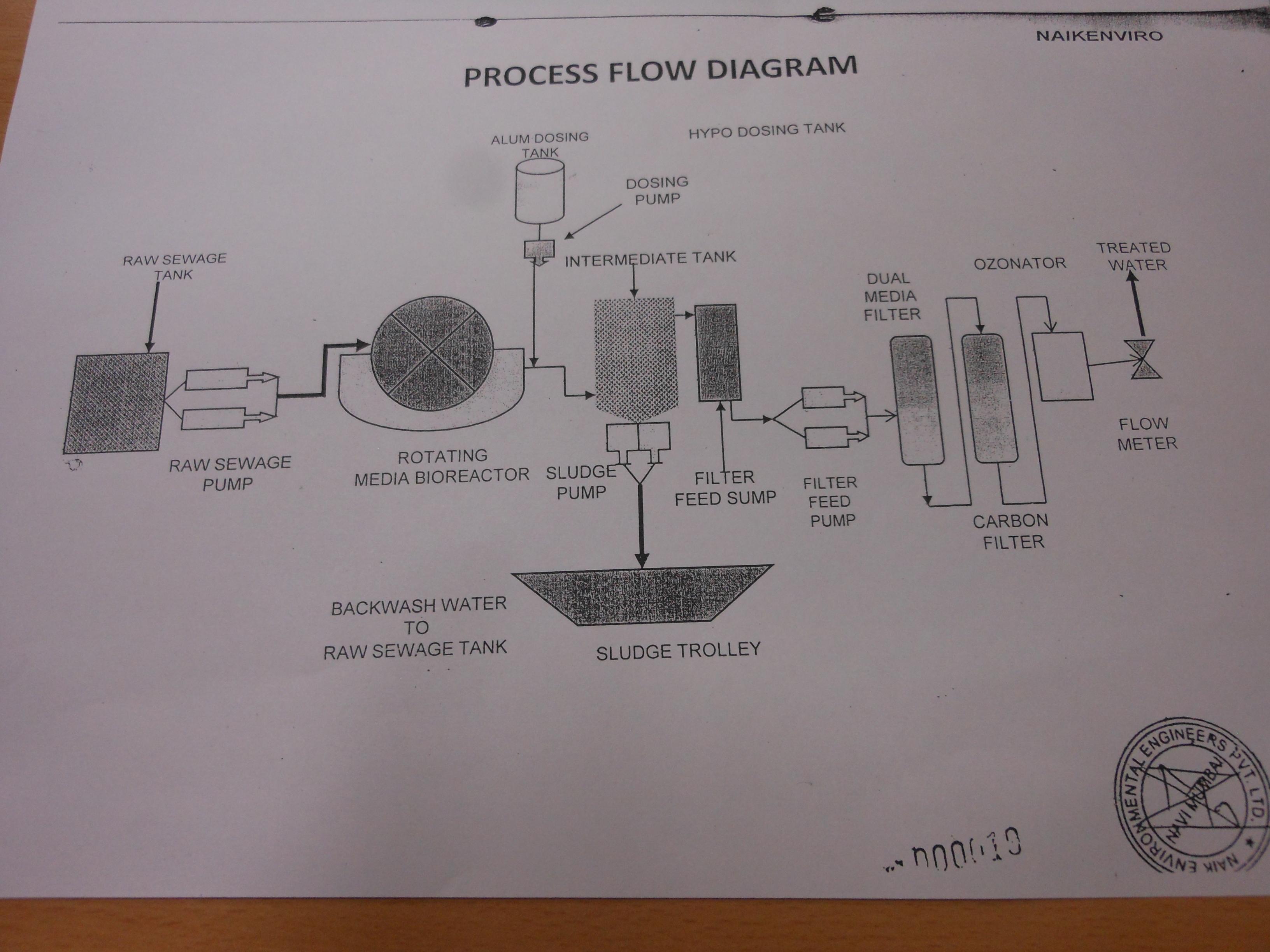

Sewage Water from the Institute,mess,hostels,quarters and the entire campus flows through an inlet pipe into the large machine, the RMBR (Rotating Media Bioreactor), inside the STP, where oxidation takes place. The outlet of the RMBR connects to an outside tank ,where it is treated with alum and stored for what is called the Primary Treatment. When the sedimentation of the wastes takes place after a certain period , the supernatant is carefully removed by pipe to Secondary Treatment chamber, which is a double chamber attached by pipes only. The bottom sediments of the sewage from the primary treatment chamber are removed by a motor separately and dried under the sun in a sludge trolley, for drying. The effluent from the secondary treatment chambers are passed through the sand chamber followed by carbon (charcoal) chamber to the Ozonator, where it is processed and sent to Tertiary Treatment chamber through a pipe, from where, the water is released to creek and river. . After drying the sludge is converted to manure soil,which is stored in sacks behind the STP and given to farmers and gardeners. Chlorinated water is sprinkled by the workers in and around the area of STP.

Fig:1 STP Unit in IIT Kamand Campus.

Fig: 2 Process Flow Diagram of STP

Fig: 3 Primary Treatment Chamber

Fig:4 Secondary Treatment Chamber

Fig: 5 Two Filter Chambers Left one is the Carbon (Charcoal filter)and the Right one is the sand filter Chamber

Fig:6 RMBR (Rotating Media Bioreactor and Ozonator)

Fig: 7 Trolley for drying of Sludge

Fig: 8 Sack of stored manure after sun-drying

Fig: 9 BOD Incubator and Hot Air Oven inside the room attached with STP.

Fig: 10 Reagents for performing BOD tests

Some Future Prospects and Plan: Recycling of the STP effluent after tertiary treatment and re-using the water in toilet flushes. Installation of sludge digester and tank for biogas storage after production. This biogas can be used for several purposes in the campus. There can be small chambers comprising of porous sand in every outlet of washbasins and sinks, where, the dirts and food remnants are trapped and therefore seperated from the water. These wastes can be collected and used for composting or preparing fertilizers,the seperated water,then passes through the inlet of the STP for treatment. In this way, the sewage effluent can be made better for re-use.The dried waste from the STP can be used by the local farmers as manure.